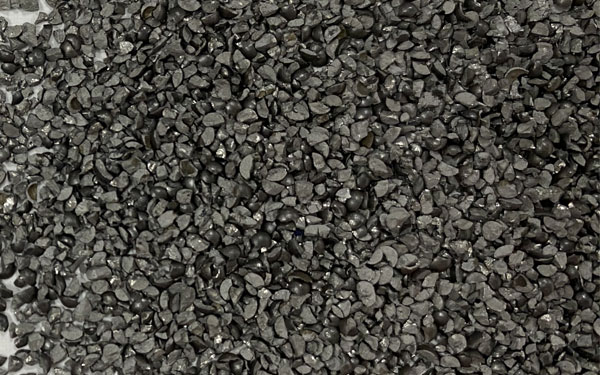

Cast steel shots are naturally formed by scraping steel through centrifugal furnace heating and centrifugal atomization. Cast steel grit is scrap steel broken by steel shots.

Nowadays, as people have more and more strict requirements on the process, the demand for steel shots is increasing, and there is a market when there is demand, so many many steel shot manufacturers are springing up like mushrooms.

Let steel shots be reused depends on these points. The use of steel shots is very wide and the price is low, so it is loved by many manufacturers.

Stainless steel shots are widely used in surface treatment of non-ferrous metal die castings, castings, aluminum profiles, auto parts, machinery manufacturing, hardware, pump valve industry.

Steel shots, because of their special superior performance, are widely used in various fields, such as castings, forgings, and machined parts surface treatment and parts heat treatment surface treatment.

The steel shot is a loss item during the shot blasting process. New steel shots should be added from time to time according to the amount of remaining steel shots and the size of the wear.

I have been explaining the relevant knowledge of steel shot before. Today I will share with you the extraction method of steel grit. Let's take a look together.

In the surface treatment process of steel materials, an impeller rotating at high speed is used to throw steel shots, steel grit, or iron shots and hit the surface of the part at high speed to remove the oxide layer on the surface of the part.

News Center

Product Center

Contact Us

Address: No. 21, North Industrial Road, Licheng District, Jinan City, Shandong Province

Phone: Manager Hu

mobile station

© 2020 Ow (Shandong) Metal Abrasives Co., Ltd. Copyright © 2020 All Rights Reserved 鲁ICP备19036183号-2 Powered by www.300.cn JINAN